Phased array for high speed inspection

The most common high speed inspections are for plate, bar and tube. System providers are often asked to meet challenging requirements in terms of inspection speed.

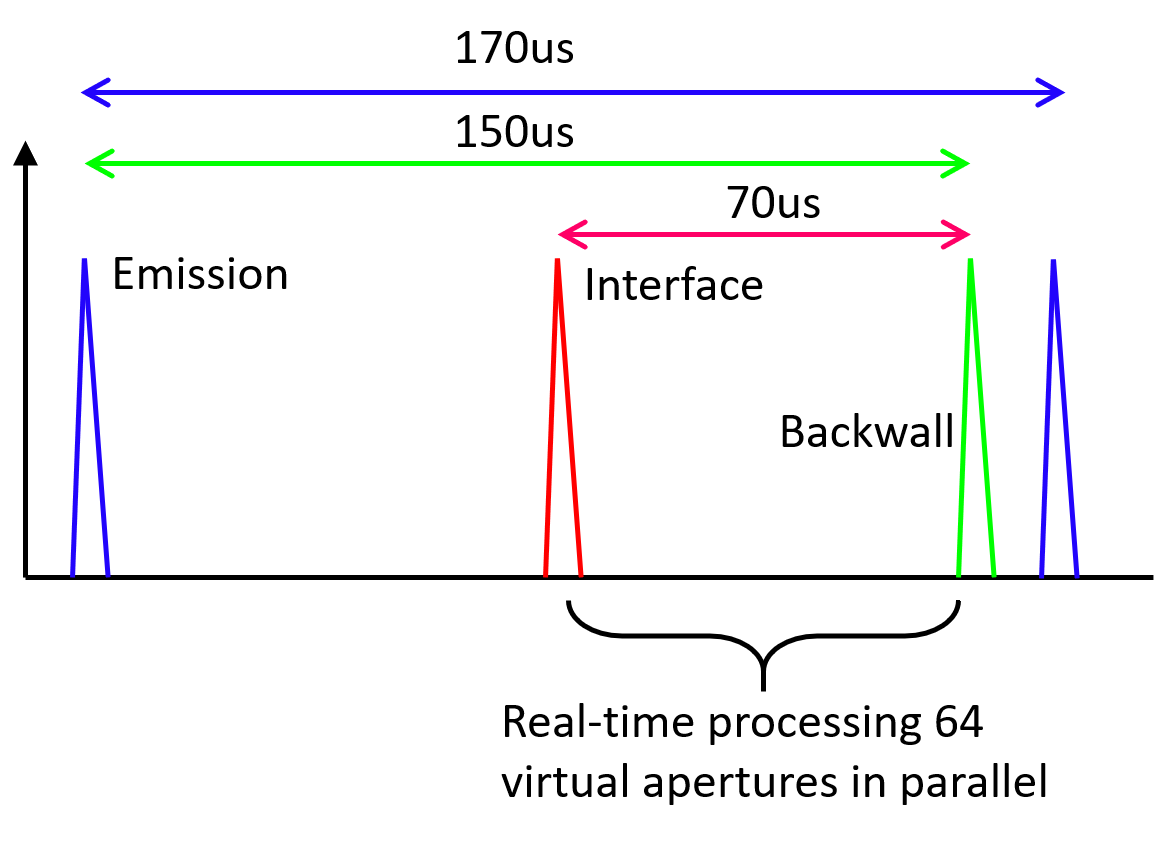

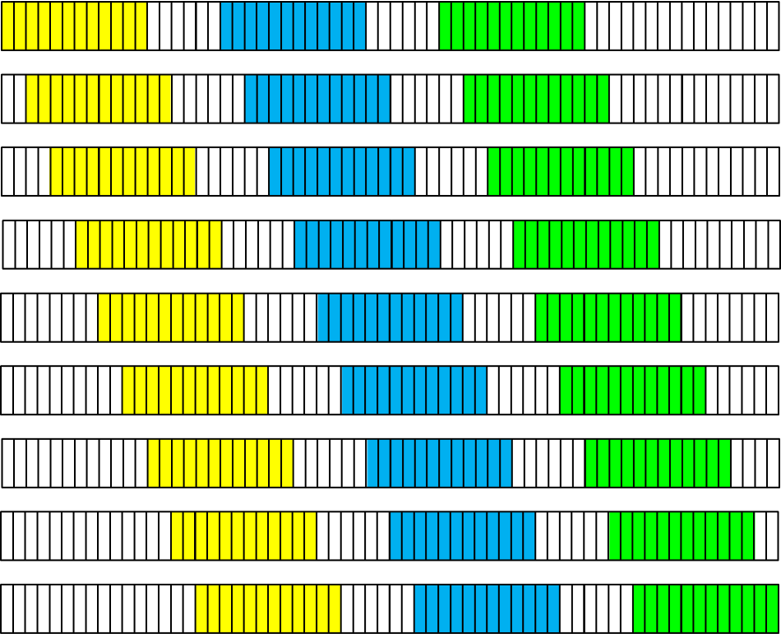

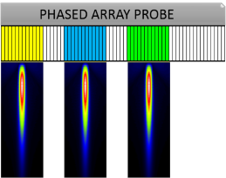

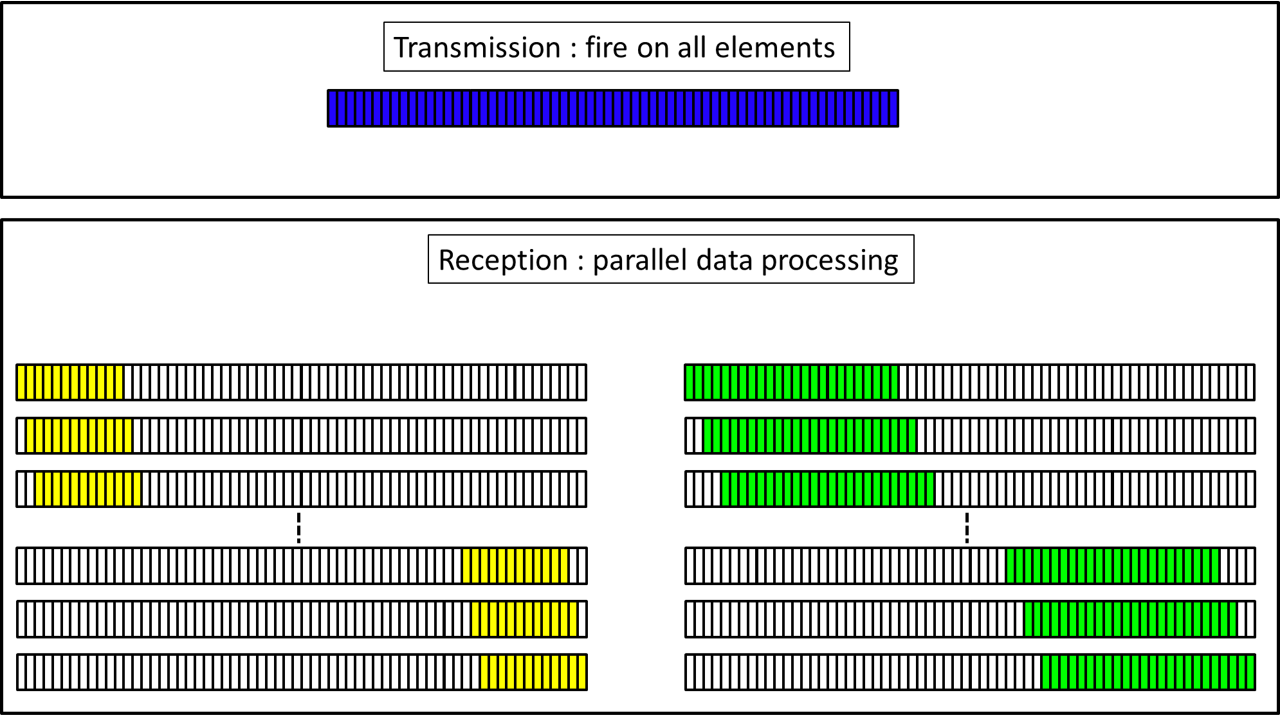

With the SOCOSWIFT+ you can meet the most demanding specification thanks to the fastest Scanning Mode available on the market. In fact with this phased array instrument you can process 64 virtual apertures in parallel !

Read below to discover the different methods and application where this parallel data processing becomes a big advantage.

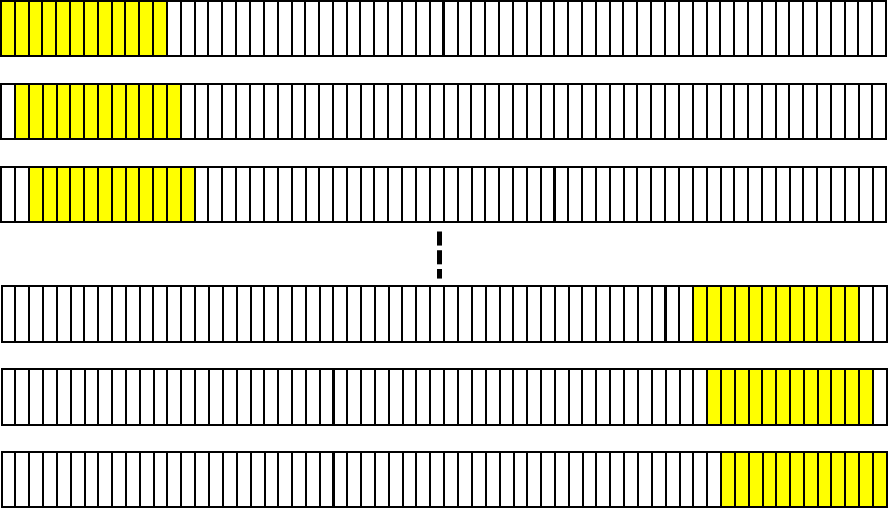

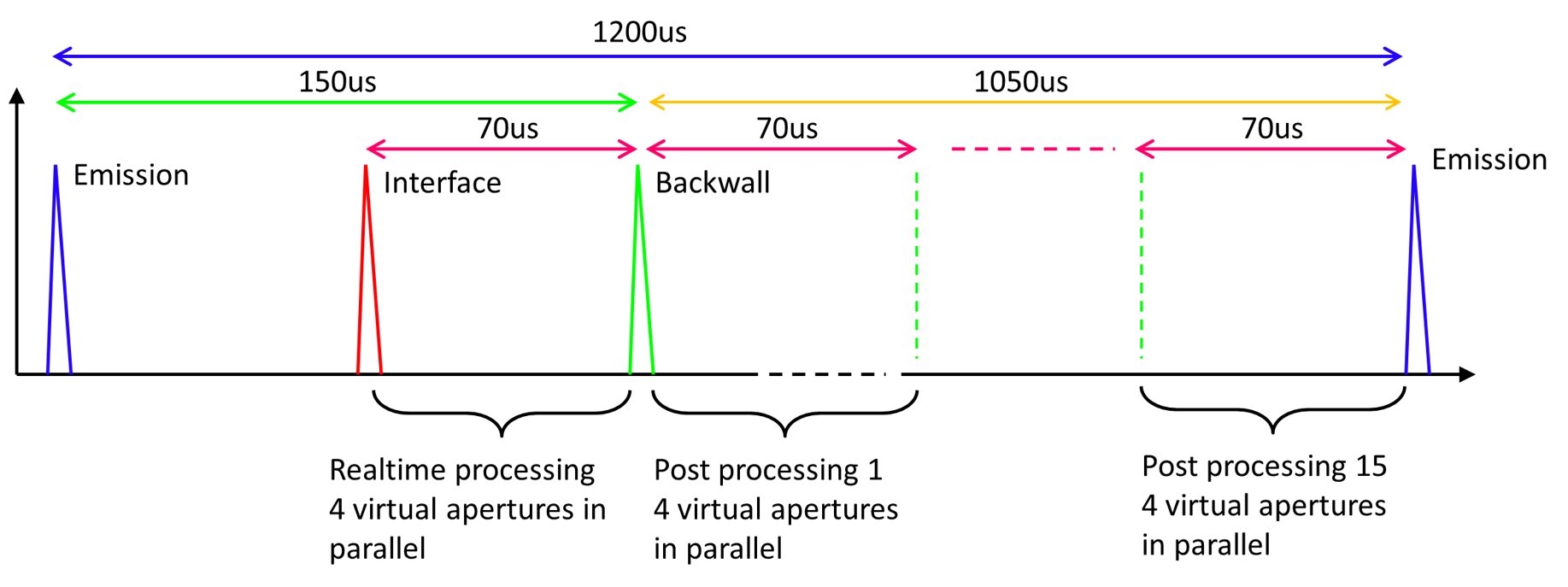

We can see that the total inspection time for 1 cycle is 1200µs because you have to post-process sequentially all your 64 virtual apertures 4 by 4. It means you can have a PRF of 833Hz.

We can see that the total inspection time for 1 cycle is 1200µs because you have to post-process sequentially all your 64 virtual apertures 4 by 4. It means you can have a PRF of 833Hz.