T.Rota system is the best solution available on the market, in terms of price, quality and reliability. It offers a high precision tube and bar UT inspection for in-line high speed flaw detection and/or dimensional measurement of outside diameter, thickness, internal diameter, eccentricity, and ovality, the whole in real time.

This solution is usable when retrofiting old electronics in place or when installing a new line. When equiping your lines with our T.Rota, it is easily adaptable to any supervisor interface or PLC (programmable logic controller), analogical or numerical. If needed, Socomate is able to supply a supervisor interface.

Furthermore, the solution can fit with the needs, either for flaw detection and, or dimensional measurement.

To increase your confidence, we got several references such as Vallourec, Valinox Nuclear, Sandvik, Sotep…

Flaw detection:

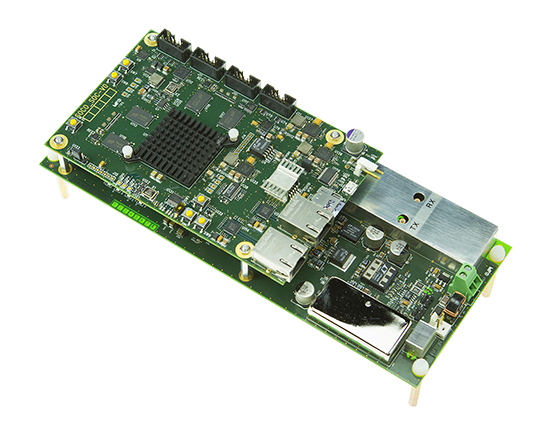

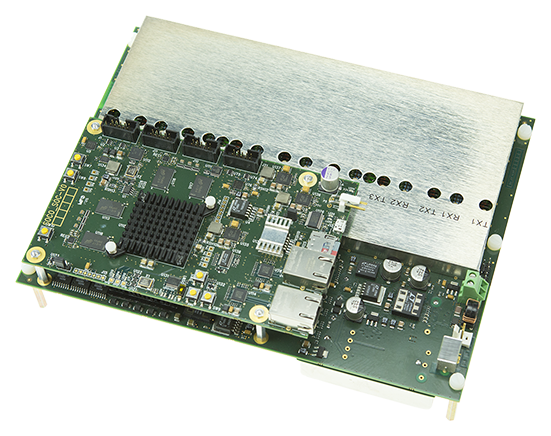

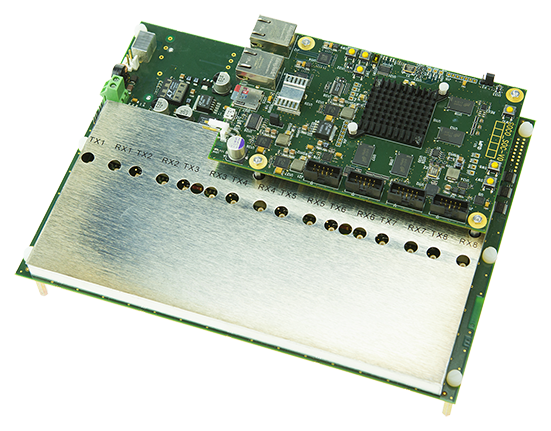

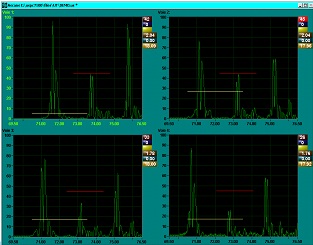

Equiped with a minimum of 4 USPC7100LA single channel Ultrasonic PCI cards firing in parallel at up to 20 kHz PRF. T.Rota performances are recognized internationally for the detection of small defects in precision tube including those for aircraft and nuclear markets.

Raise the quality of tube and bar with the T.Rota at very competitive price.

Dimensional measurement :

Equiped with 3 USPC7100LA, single channel ultrasonic PCI cards firing in parallel at up to 20 kHz PRF.

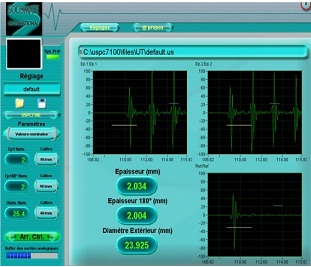

Benefit from Socomate’s software, a real time acquisition to measure wall thickness and external diameter from which it calculates, always in real time, internal diameter, eccentricity, and ovality with a resolution better than 1µm.

Subject to the rotary head performances, the measurement accuracy could be ± 3µm.

Rotary head with T.Rota

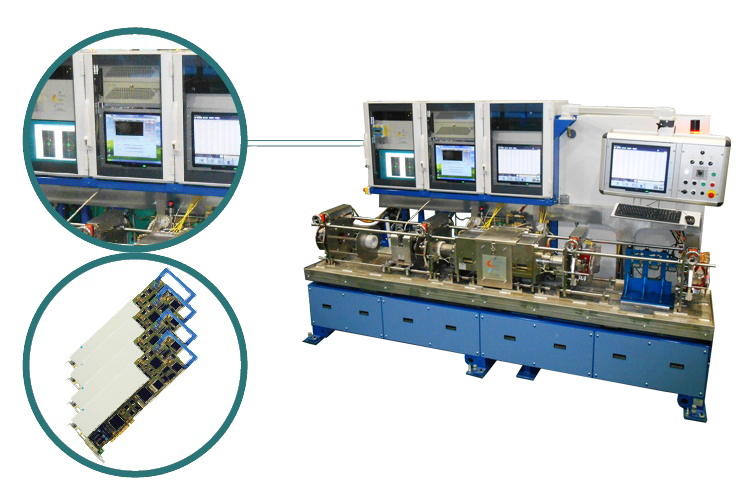

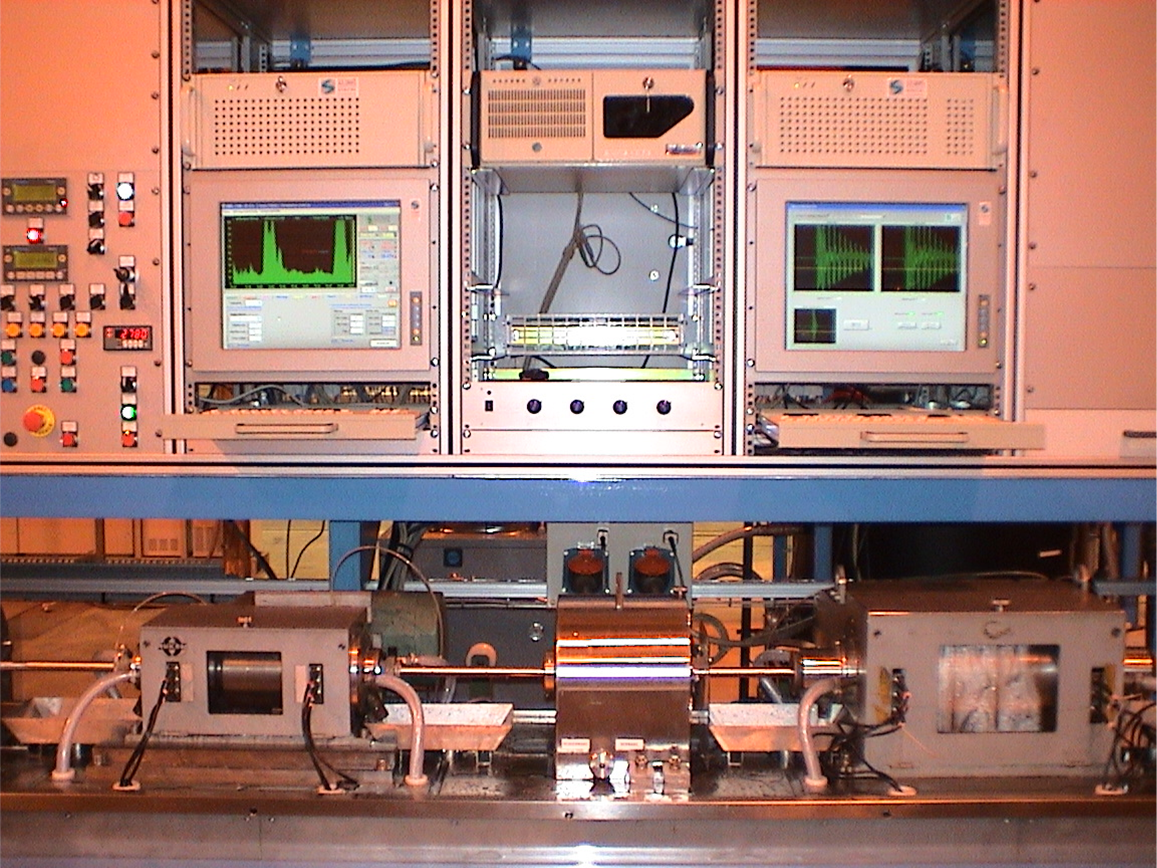

Our partner CMS has integrated into one of its rotary head our T.Rota system for Flaw detection and Dimensional measurement.

Defect s ...

T.Rota flaw detection and dimensional measurement

T.Rota for Flaw detection and Dimensional measurement on Nukem rotary head (ROTA25©).

Reference : Valinox