The process, according to the patent, aims at the dimensional characterization of tube at very high speed with extremely simple mechanics, avoiding all mechanical rotation either of tube or transducers. e.Rota offers 100% full dimensional measurement of tube: thickness, external and internal diameters, eccentricity and ovality.

The patented software, supply real time data acquisition and processing which allows its utilization on production line where rotary heads are usually installed.

As an alternative to rotary heads, this solution provides a high increase of measurement data, and reduces what are expensive such as mechanical purchasing price, maintenance costs and the setting times

This system is usable for tubes in such industries: Nuclear, Aircraft, Oil & gas, Automotive, Umbilical.

Take the benefit of several references in big groups, such as Vallourec, Salzgitter Mannesmann, Oväko.

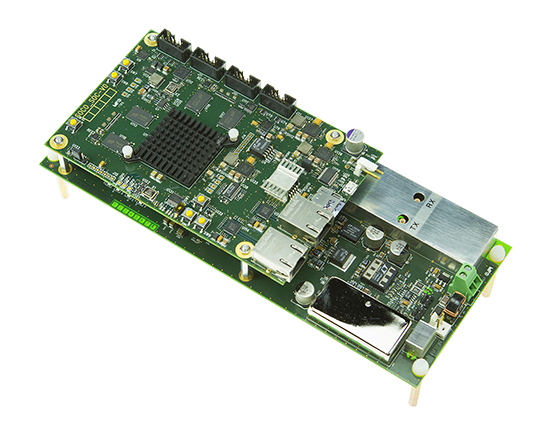

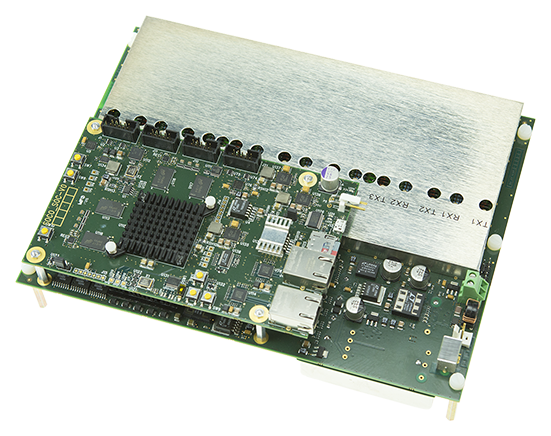

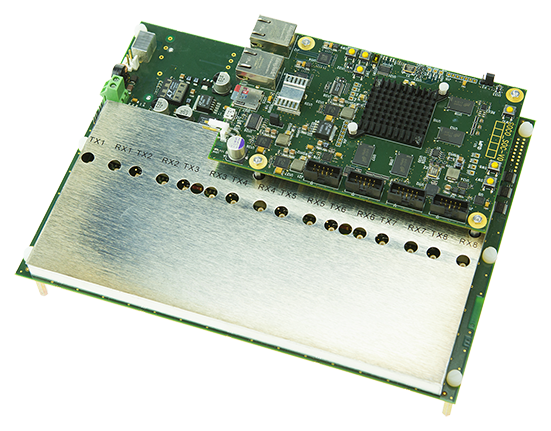

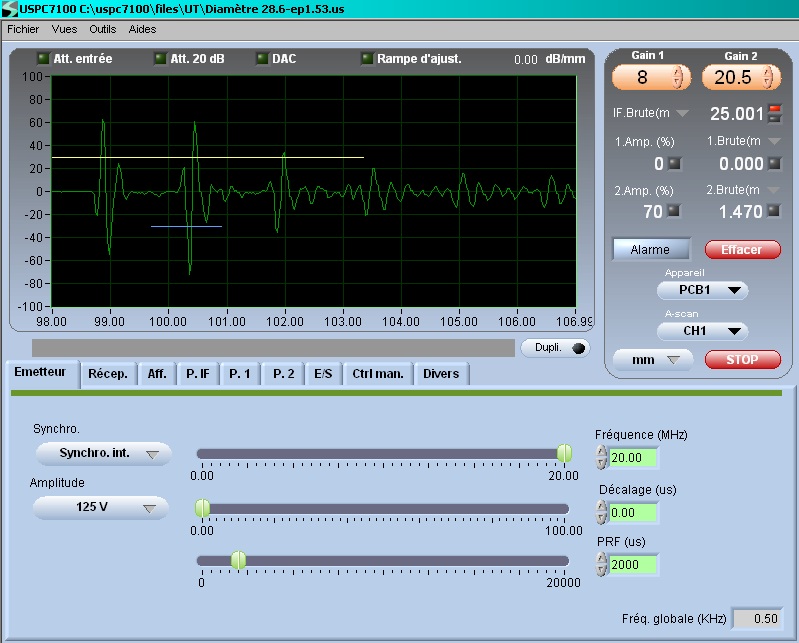

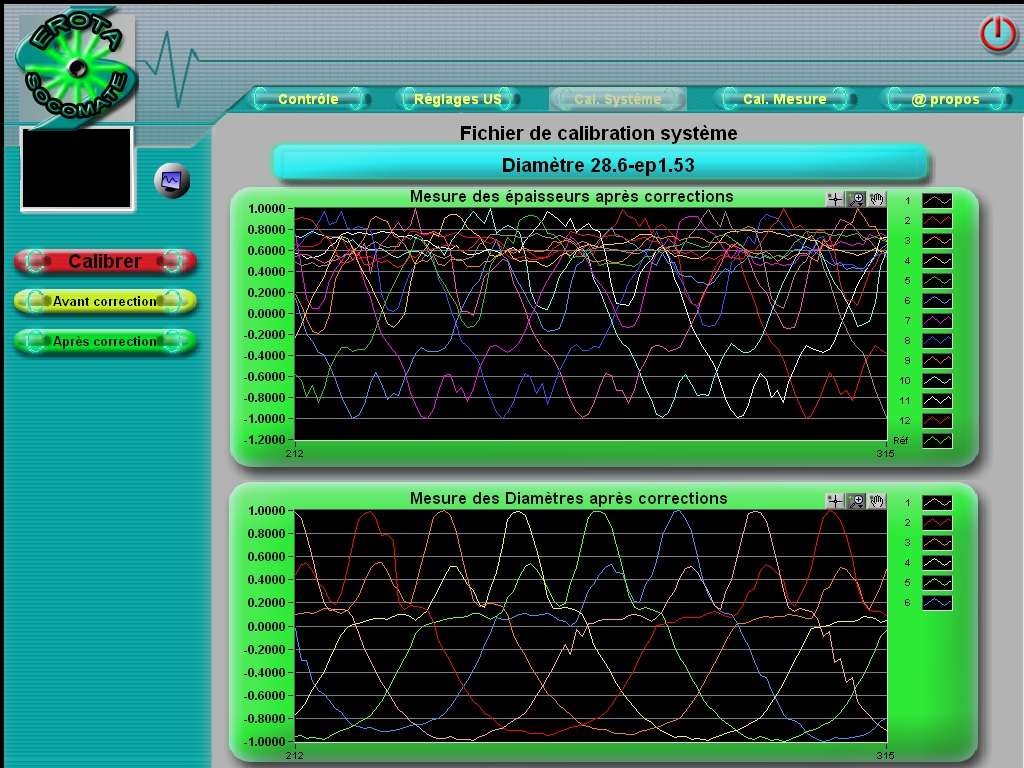

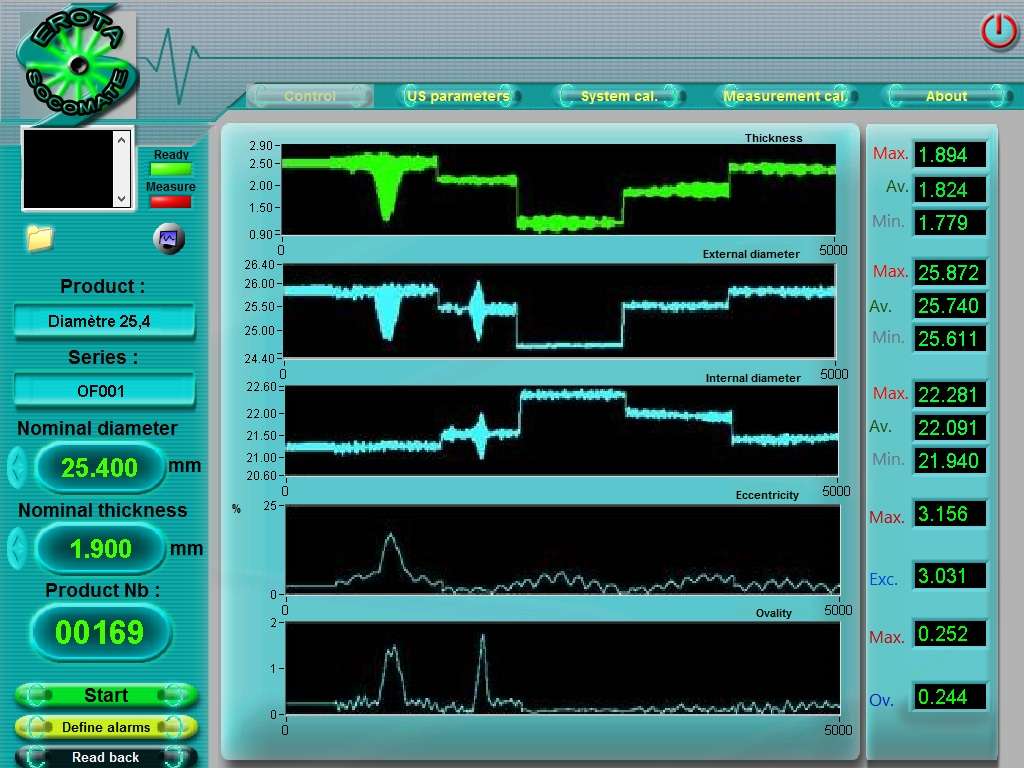

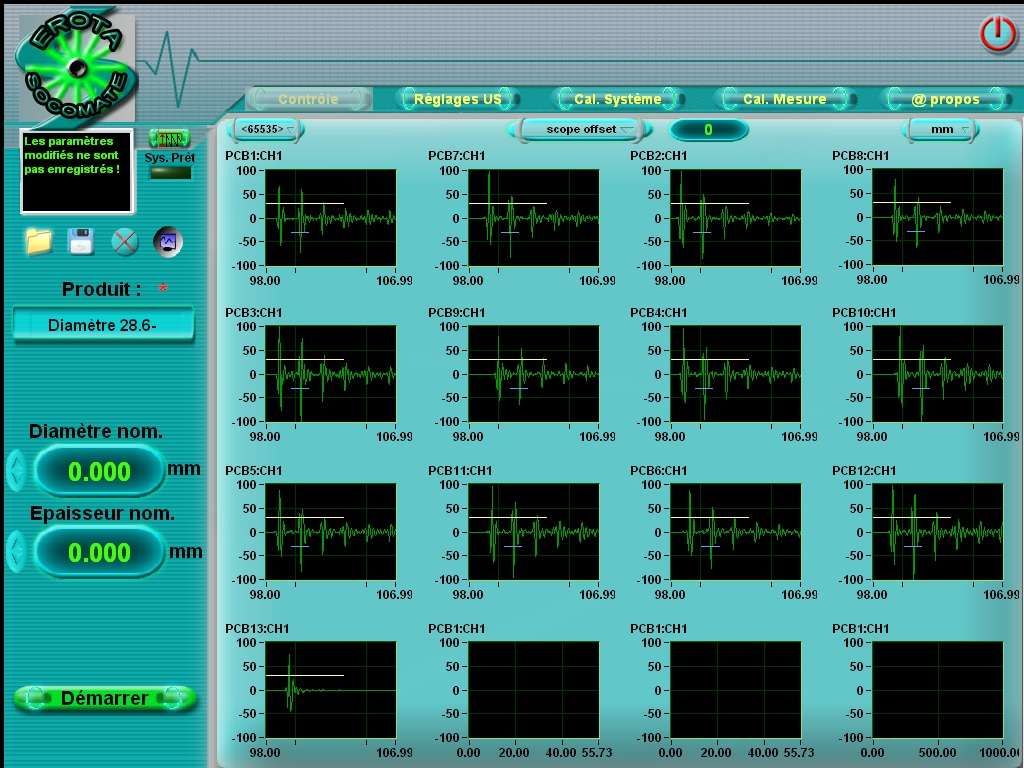

As an example, these are some pictures of our e.Rota Software to illustrate:

USPC7100 standard software interface for ultrasonic settings

e.Rota offset calibration

Dimensional measurements results from e.Rota. Stripchart type representation

Multi A-Scan display

Advantages : |

|---|

| High increase of data acquisition |

| Affordable purchasing price |

| All types of tube with a regular & clean surface |

| e.Rota solution can be easily adapted for use on existing linear testing benches currently using rotary heads, encircling EC probes, phased array multielement probes, etc… |

This e.Rota solution offers the possibility to be upgraded with our FAAST phased Array system to get a 2 in 1 solution, dimensional measurement and flaw detection.

Meaning that it is possible to have the e.Rota alone, the FAAST alone, or both together according to the need.

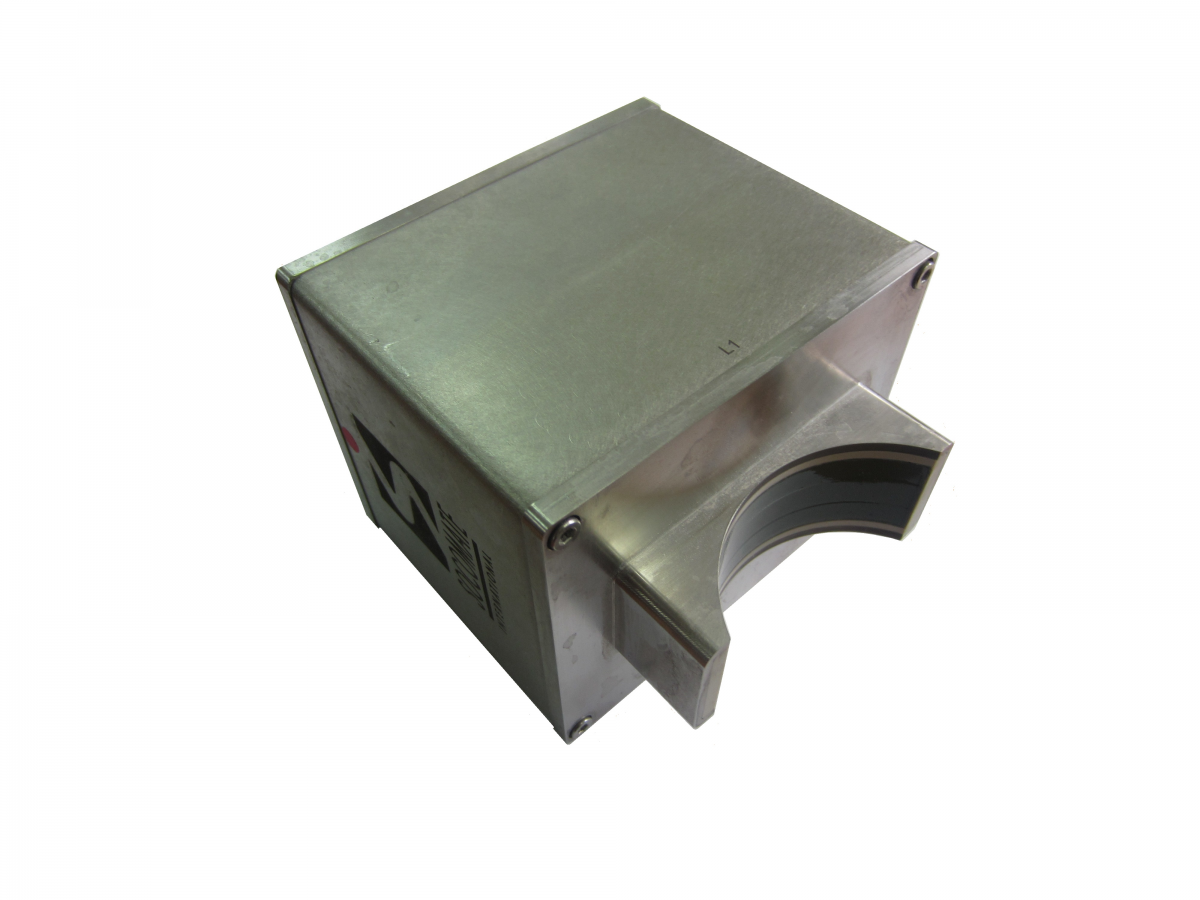

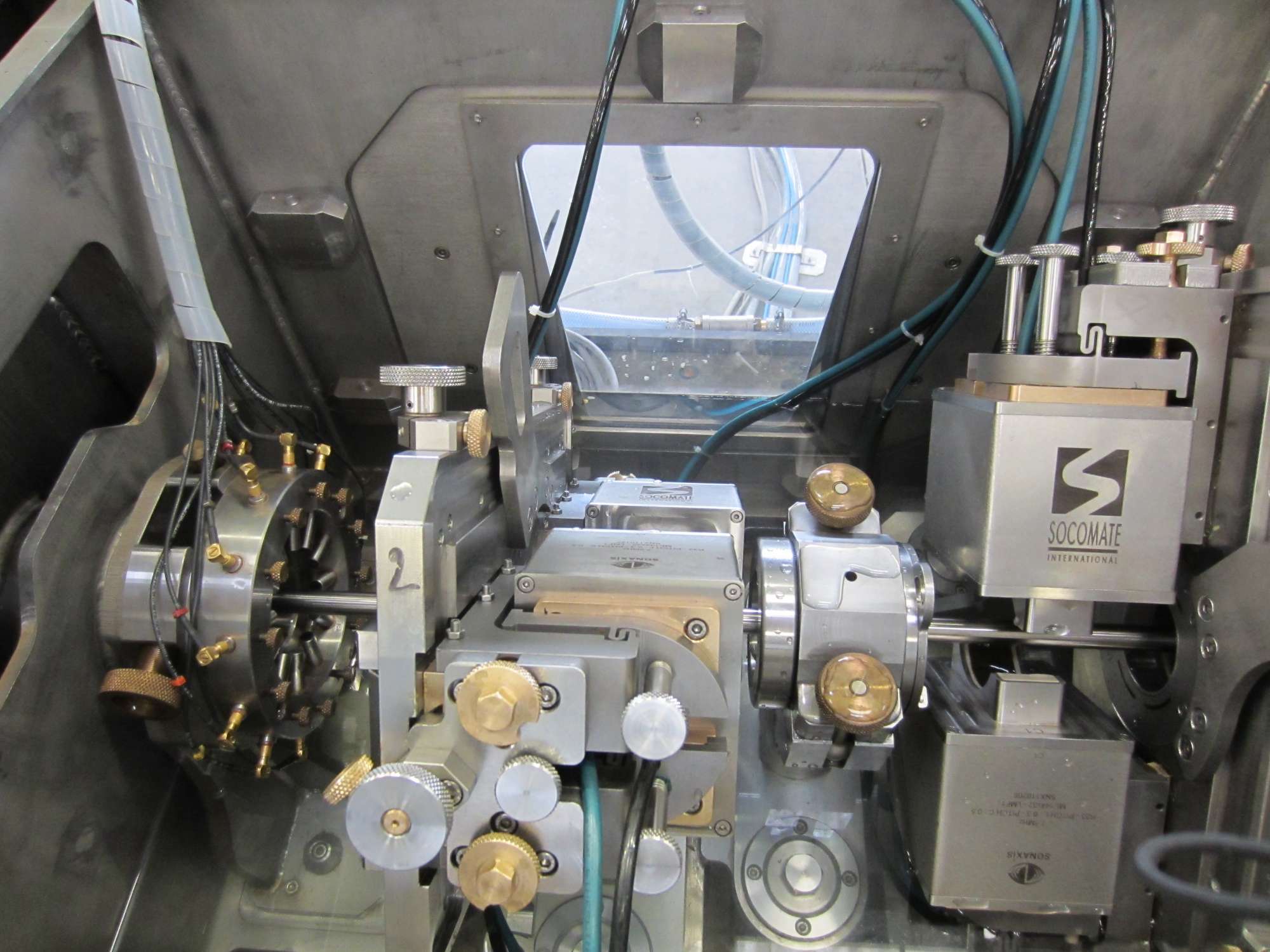

Both solution are integrated into a simple immersion tank. The FAAST Phased Array is used to detect longitudinal and transversal flaws in 2 plans with only 1 set of probes which is composed of 4 Bi-linear multielement ring probes.

Bi-linear ring probe

32x144 Elements

| Example for umbilical tube inspection from a reference: |

|---|

| Tube diameter range: 15 – 50 mm |

| Tube thickness: 1.0 to 4.0 mm |

| Longitudinal and Transversal, inner and outer, flaw notches detection. |

| Minimum flaw depth: 5% Wall Thickness |

| Linear Tube Speed: Up to 12meters/mn |

| 4x Bi-Linear ring probes 32x144 elements – 7.5 MHz |

| Easy maintenance |

REFERENCES

Dimensional measurement

e.Rota evaluation bench for full dimensional measurement of high precision tubing on ROTA25© (Nukem) inspect ...

Umbilical tubing inspection

e.Rota system combined with our FAAST Technology is an alternative to rotary head for Flaw detection and Dimensional measurement of high preci ...