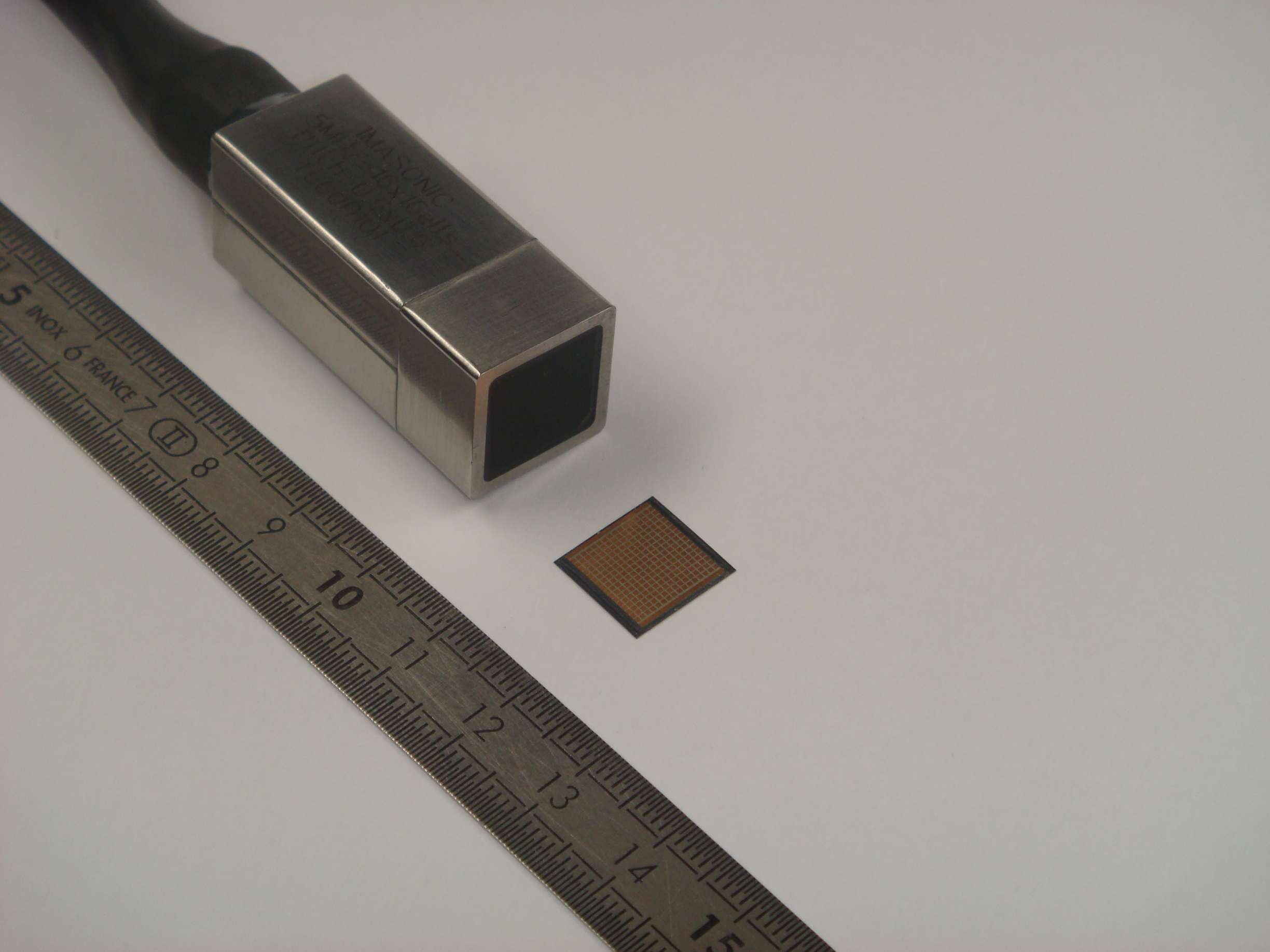

A transducer converts one form of energy into another, meaning a piezoelectric crystal converts electric energy into ultrasound energy, and reversely. Defining the right probe is the most important task to prepare for an application.

In fact, Phased Array probe should be determined even before selecting an instrument. Within Non Destructive Testing, and especially Phased Array ultrasonic testing, there are several types of probes each one dedicated to a specific area of application.

Phased Array probes can be standard or customized, and in front of a wide choice of shapes, sizes, frequencies and number of elements, it can appear to be a challenge choosing the good one. Hereafter is an introduction of some:

1D Linear Array probe:

The 1D linear is a Phased Array transducer with a vast majority of applications in its portfolio, and several configurations are now defined as standards. Like conventional UT, a 1D array probe can generate and receive an ultrasonic beam. Basic skills are beam steering, focusing, and electronic scanning in a single plane defined perpendicularly to the line of elements in the array.

The pitch is the distance center to center between each element. When defined as ʎ/2, it allows steering the beam without producing any grating lobe in the inspected material, it also defines today the current standard for designing the Phased Array probes. For single electronic scanning, a larger pitch can be defined to provide an increased coverage for better productivity.

Based on the application, required productivity and coverage, it is more or less a long transducer following the number of elements. Most common applications in regards to automated inspection system will meet the requirements for plate inspection, bars & billets inspection, composite inspection, tubes & pipes inspection, rail inspection, turbine discs, including reliable detection of surface, subsurface and wall thickness measurements.

2D Matrix probe:

This type of Phased Array probes have the capability to deflect beams in several planes thanks to its elements spread on a 2D aperture, giving the ability to perform a complete volumetric inspection. When requiring to deflect beam within 3D space, the formula ʎ/2 need to be applied in both directions, potentially leading to a high number of elements.

Another advantage of such Phased Array transducer is to combine focusing and beam steering. In one direction we will use traditional ʎ/2 formula with the right pitch to reach the desired angle. On second direction we would use a larger pitch to adapt the focal depth, leading to an increase of energy of the beam, allowing thus better sensitivity and resolution.

For each application that requires the use of a 2D Ultrasound Phased Array probe, one objective is to maximize the reduction of elements to limit the cost, while keeping good acoustical results.

Matrix probes can be used to detect cracks in complex parts as for nozzle where the 3D geometry requires 3D beam steering skills.

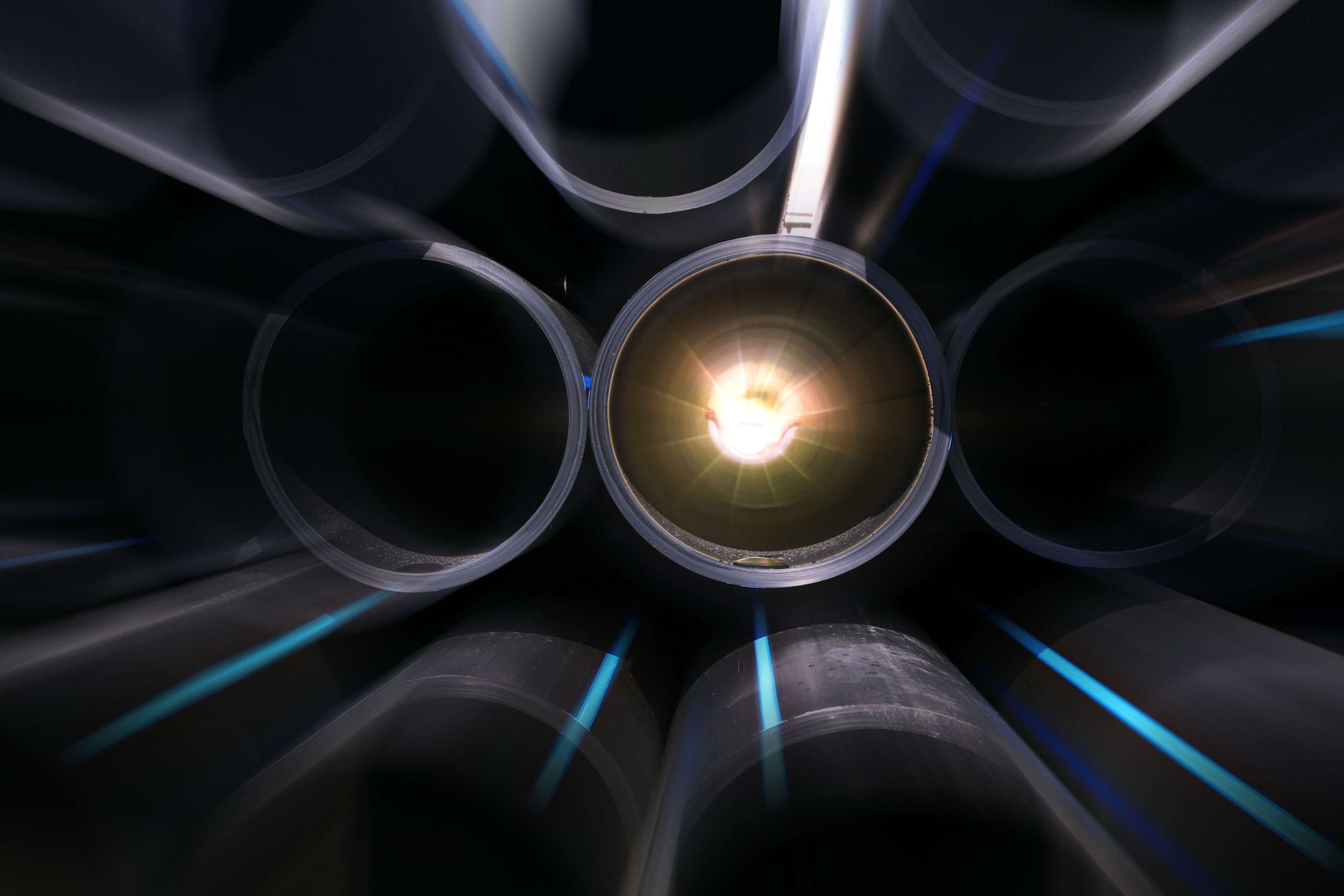

TRL Probes:

TRL probes, based on both conventional and Phased Array probes, are dedicated to near surface inspections and enhanced focusing in complex material. Such Phased Array transducer combines two linear or matrix probes acting as separate transmitter and receiver, both settled on a common wedge to produce a focal area at the crossing of the two beams.

With the use of Ultrasound Phased Array TRL probes, also called dual array probes, it combines the advantages of acoustics to the versatility of Phased Array to provide efficient inspection close to the surface in rough structures. An example of application where such probe is performing well is weld inspection on complex materials.